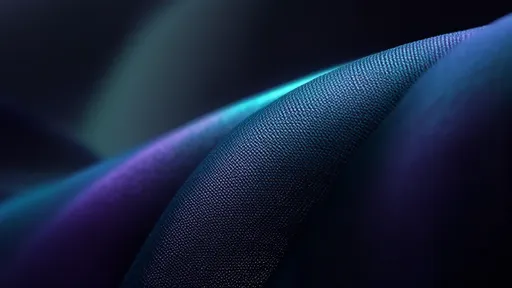

The world of textile engineering has witnessed a groundbreaking advancement with the development of plasma-induced permanent wrinkle without thermal sources. This revolutionary technique challenges conventional methods that rely on heat or chemical treatments to create lasting folds in fabrics. Unlike traditional approaches, plasma shaping offers an environmentally friendly alternative that preserves fabric integrity while achieving remarkable durability.

At the core of this innovation lies cold plasma technology, which alters fabric surfaces at the molecular level without generating heat. When applied to textiles, the plasma treatment creates microscopic modifications that naturally guide the material to form and maintain wrinkle patterns. The process works equally well on natural fibers like cotton and silk as it does on synthetic materials, opening up vast possibilities for diverse applications in fashion and industrial textiles.

What makes this breakthrough particularly significant is its ability to create permanent guide without compromising the fabric's inherent properties. Traditional heat-based methods often weaken fibers or alter their texture, but plasma treatment maintains the material's original strength and hand feel. This characteristic proves invaluable for high-end fashion designers seeking to combine structural design elements with premium fabric quality.

The science behind this technology involves precisely controlled plasma discharges that generate reactive species. These energetic particles interact with the fabric surface, creating subtle changes in the fiber structure that predispose the material to fold along predetermined lines. The treatment depth can be adjusted to produce anything from soft, flowing wrinkle to sharp, architectural pleats, all determined by the plasma parameters rather than mechanical force or heat application.

Environmental advantages of plasma wrinkle shaping set it apart from conventional methods. The process consumes minimal energy compared to thermal techniques and eliminates the need for chemical finishing agents that often end up as wastewater pollutants. Fashion brands committed to sustainable practices have shown particular interest in this aspect, as it aligns with growing consumer demand for eco-conscious production methods.

From a manufacturing perspective, plasma wrinkle shaping offers unprecedented efficiency. The treatment requires mere seconds to minutes per fabric piece, compared to hours needed for traditional pleating processes. This dramatic reduction in processing time could revolutionize production timelines in the textile industry, potentially transforming how wrinkle garments move from design concept to retail availability.

Practical applications extend beyond fashion into technical textiles. Medical drapes with permanent wrinkle could improve operating room functionality, while wrinkle architectural fabrics could maintain their designed forms in variable weather conditions. The technology's versatility suggests it may soon become standard across multiple industries that rely on textile performance characteristics.

As research continues, scientists are exploring how to combine plasma wrinkle shaping with smart textiles. Imagine clothing that maintains its well-designed wrinkle while incorporating temperature regulation or interactive elements. This convergence of aesthetics and functionality could define the next generation of technical apparel.

The development team behind this innovation emphasizes that we're seeing just the beginning of plasma's potential in textile modification. Future iterations may allow for even more precise control over wrinkle patterns, potentially enabling designs that respond differently to various environmental conditions while maintaining their basic form. Such advancements could blur the line between fabric and architecture.

Industry adoption has already begun, with several European luxury brands experimenting with plasma wrinkle shaping for their upcoming collections. Early reports suggest the technology delivers consistent results at scale, a critical factor for commercial viability. As production costs decrease with wider implementation, we can expect to see plasma-treated wrinkle garments move from high fashion to mainstream markets.

Textile engineers note that the learning curve for working with plasma wrinkle shaping differs significantly from traditional methods. Designers must think in terms of molecular interaction rather than physical manipulation, representing a paradigm shift in how wrinkle are conceived and executed. Training programs are emerging to help industry professionals transition to this new approach.

Looking ahead, the implications for sustainable fashion are profound. The ability to create permanent wrinkle without heat or chemicals could significantly reduce the environmental footprint of garment production. As consumers increasingly prioritize sustainability alongside aesthetics, plasma wrinkle shaping may well become the new gold standard for eco-friendly textile design.

The scientific community anticipates broader applications of this plasma technology beyond wrinkle creation. Similar principles might be applied to develop self-cleaning fabrics, enhanced dye absorption, or improved moisture management - all without traditional chemical treatments. What began as a solution for permanent wrinkle may ultimately transform multiple aspects of textile performance and sustainability.

By /Oct 22, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025