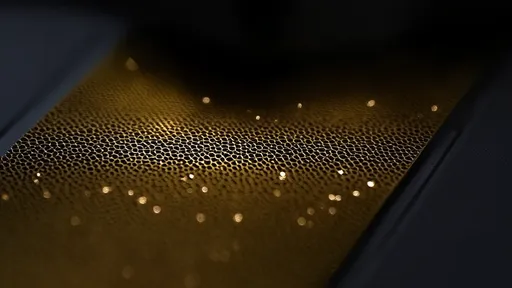

The world of advanced materials has witnessed a groundbreaking innovation with the development of 0.01mm gold foil coatings for nanoscale metallic fabrics. This ultra-thin gold foil, measuring a mere 10 micrometers in thickness, represents a significant leap forward in the field of functional textiles and wearable technology. Researchers and material scientists are hailing this development as a potential game-changer for industries ranging from fashion to medical technology.

What makes this 0.01mm gold foil coating particularly remarkable is its ability to maintain the luxurious properties of gold while achieving unprecedented flexibility and durability at the nanoscale. Unlike traditional gold leaf or thicker gold platings, this ultra-thin version can be applied to various fabric substrates without compromising the material's natural drape or breathability. The coating process involves advanced deposition techniques that allow the gold to bond at a molecular level with textile fibers, creating a seamless metallic surface that resists cracking or peeling.

The applications of this technology span multiple industries. In haute couture, designers are experimenting with gold-coated fabrics that shimmer with authentic gold's luster while remaining supple enough for flowing garments. The medical field sees potential for antimicrobial fabrics in hospital settings, as gold nanoparticles have long been known for their bacteria-resistant properties. Electronics manufacturers are particularly excited about the possibilities for wearable technology, where the conductive properties of gold could be integrated directly into clothing for health monitoring or communication purposes.

From a technical perspective, creating stable 0.01mm gold foil coatings presented numerous challenges. The research team had to develop specialized alloy compositions that would prevent the gold from becoming brittle at such thin dimensions. They also engineered novel application methods that ensure even distribution across fabric surfaces, including complex three-dimensional textile structures. The result is a coating that maintains its integrity through repeated stretching, folding, and washing cycles that would cause conventional metallic finishes to fail.

Environmental considerations played a significant role in the development process. While gold is inherently valuable and recyclable, the researchers focused on minimizing material waste during application. Their deposition technique achieves near-perfect material utilization, with less than 2% of the gold going to waste during the coating process. This efficiency makes the technology more sustainable than traditional metal coating methods while still delivering the premium qualities associated with gold.

The commercial potential of 0.01mm gold foil fabrics is already attracting attention from major brands and investors. Early prototypes have demonstrated excellent performance in stress tests, maintaining their appearance and functionality through equivalent of years of regular use. Industry analysts predict that initial products featuring this technology will reach luxury markets within the next 18 months, with broader applications following as production scales up and costs decrease.

Looking ahead, researchers are exploring ways to enhance the technology further. Current investigations include developing color variations through alloying techniques that could produce rose gold or white gold fabric finishes without compromising the material's beneficial properties. Another promising avenue involves creating gradient coatings that vary in thickness across a single garment, allowing for innovative design possibilities and functional zoning in smart clothing applications.

As this technology matures, it may redefine our relationship with precious metals in everyday materials. The successful development of 0.01mm gold foil coatings proves that advanced materials can combine luxury with practicality, tradition with innovation. While gold has adorned human civilization for millennia, its application in this ultra-thin, flexible form represents an entirely new chapter in material science - one that could see gold becoming as common in our clothing as it has been in our jewelry and electronics.

By /Oct 22, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025