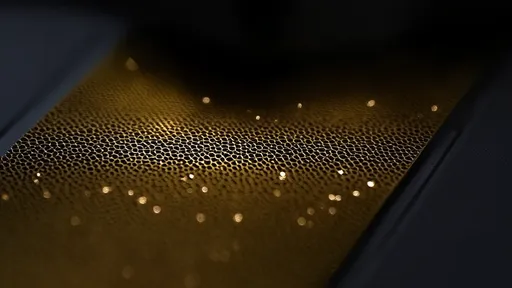

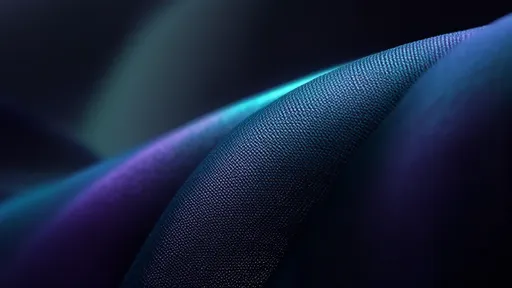

The intersection of art and technology has always been a fertile ground for innovation, but few developments have been as breathtaking as the recent breakthroughs in micro-engraving techniques. Among these, the ability to laser-carve submicron pores into delicate materials like lace represents a leap forward in precision engineering. This process, which merges the intricacy of traditional craftsmanship with cutting-edge laser technology, is redefining the boundaries of what’s possible in both decorative and functional textiles.

At the heart of this advancement lies the use of ultrafast lasers capable of creating pores smaller than a micron in diameter. These lasers operate at pulse durations measured in femtoseconds, allowing for unparalleled control over the material’s surface. Unlike conventional methods, which often result in thermal damage or rough edges, femtosecond lasers vaporize material so quickly that the surrounding area remains unaffected. This precision is critical when working with fragile fabrics like lace, where even the slightest imperfection can compromise the integrity of the design.

The applications of this technology extend far beyond aesthetics. In biomedical engineering, for instance, micro-engraved lace can serve as a scaffold for tissue regeneration. The submicron pores mimic the extracellular matrix, providing an ideal environment for cell growth. Similarly, in filtration systems, the ability to control pore size with such precision allows for the creation of membranes that can separate particles at a molecular level. These membranes are already being tested for use in water purification and air filtration, where their efficiency outperforms traditional materials.

What makes this technique particularly remarkable is its scalability. While the initial research focused on small-scale prototypes, recent developments have demonstrated that the process can be adapted for industrial production. This opens up possibilities for mass-producing textiles with customized microstructures, tailored to specific functions. Imagine athletic wear that regulates temperature through strategically placed pores, or architectural fabrics that filter sunlight while maintaining transparency. The potential is vast, and we’re only beginning to explore it.

Of course, challenges remain. The cost of femtosecond laser systems is still prohibitive for many manufacturers, and the process requires a level of expertise that isn’t yet widespread. However, as the technology matures and becomes more accessible, these barriers are likely to diminish. Already, collaborations between research institutions and textile companies are yielding promising results, bringing us closer to a future where micro-engraved lace is commonplace.

Beyond its practical uses, this innovation also raises fascinating questions about the nature of craftsmanship in the digital age. Can a laser-carved design be considered handmade? Where do we draw the line between art and engineering? These are questions without easy answers, but they underscore the transformative power of technologies that blur traditional distinctions. One thing is certain: as micro-engraving techniques continue to evolve, they’ll inspire new forms of creativity that we can’t yet imagine.

The journey from concept to reality has been anything but straightforward. Early attempts at micro-engraving often resulted in uneven pores or damaged materials, highlighting the need for a more refined approach. It was only through iterative experimentation—adjusting laser parameters, testing different wavelengths, and fine-tuning the focus—that researchers achieved the level of precision required. This trial-and-error process, though time-consuming, was essential for understanding the complex interplay between laser energy and material response.

Looking ahead, the next frontier may lie in combining micro-engraving with other emerging technologies. Smart textiles embedded with sensors could benefit from submicron pores that enhance breathability without compromising functionality. Similarly, advances in nanotechnology might enable the integration of conductive materials into the pores, creating fabrics that double as electronic circuits. The synergy between these fields could give rise to entirely new categories of products, further expanding the horizons of material science.

For now, though, the focus remains on perfecting the basics. Each successful experiment brings us closer to mastering the art of micro-engraving, inch by painstaking inch. And as the technology progresses, so too does our appreciation for the delicate balance between power and precision—a balance that lies at the very core of this remarkable achievement.

By /Oct 22, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025

By /Jul 25, 2025